FF&E Snagging Checklist

FF&E snagging is where a project moves from “delivered” to “handover ready”. In our experience it’s one of the most valuable steps in protecting the project’s timeline, budget and final quality.

As an FF&E partner, we typically carry out snagging on site, alongside the main contractor and client team. That shared walk around is where small issues are caught early and responsibilities are clearly agreed, helping handover remain on schedule.

This guide sets out what a solid snagging process should include, who should be involved and a practical checklist that you can download for use on your next project.

Material damages found through snagging checks.

What snagging means in FF&E and why it works best as a joint inspection

FF&E snagging is a structured quality check of all supplied furniture, fixtures and equipment before handover. It happens once items are delivered and installed to ensure:

Everything has arrived as specified.

Everything is installed correctly and safely.

Finishes and fabrics match approvals.

Items function properly and are defect-free.

Documentation and warranties are complete.

Snagging is where you check reality matches the drawings. Rooms become tight, access shifts, and site conditions vary. A snagging walkthrough gives everyone a chance to confirm:

The FF&E package matches the signed specification.

The installation meets site and safety regs.

Any issues are logged, and a plan of action is made.

That is why we recommend doing snagging with the contractor and client together. It avoids re-visits, prevents confusion over responsibility and keeps the snags list grounded in what the finished space actually needs.

Poor installation and room readiness found through checks.

What to Include in Your FF&E Snagging

-

This is where defects are most visible, and where quality is literally felt by your guests.

Check for:

Damage from Transit: pulls, tears and chips.

Correct Item & Spec: models, size, finish, fabric, trim, legs.

Fabric & Colour Match: aligns with approvals and sample sign-off.

Seams & Stitching: straight, secure, no pulls or loose threads.

Build Quality: no sagging seats, uneven cushions or creaking.

Stability: no wobbles, rocking or uneven feet.

Fixings: wall hung items are secure with no movement.

Compliance Labels: fire tags or safety marks present as required.

Supplier Note: if something looks off, snag it immediately. It is faster to resolve while the installation team is still on site.

-

Case goods can look fine at first glance, but fail on finish and alignment.

Check for:

Finish Quality: consistent tone, no scratches, glue marks or bubbling.

Edges / Corners: smooth, clean and no lifting of laminate.

Alignment: doors and drawers are flush and evenly spaced.

Hardware: handles installed securely, aligned and in the correct style.

Function: drawers glide, soft close operates and doors don’t catch.

Anchoring: tall units are fixed securely.

Glass / Mirrors: no chips or cracks, mounted correctly.

Practical Tip: Open and close every moving part once. That single action, catches half the problems.

-

Lighting snagging is about safety and specification, not just power.

Check for:

Correct Fittings: finish, size and design match the spec.

Positioning: installed at the correct height and location.

Wiring & Safety: no exposed wiring, fittings flush.

Bulb Spec: correct wattage, colour, temperature, dimmable if needed.

Switches & Controls: functional and labelled correctly.

Accessories: shades, cords, diffusers present and undamaged.

Supplier note: If lighting is split between trades, agree what is under FF&E vs the electrical team so nothing slips through.

-

Even perfect furniture can look undone as a result of rushed installation or unfinished rooms.

Check for:

Protection Removed: all films, padding, corner guards removed.

Packaging Cleared: nothing left inside units or behind furniture.

Levels & Alignment: tables level and wall items straight.

No Install Damage: floors, walls and skirtings not scuffed.

Correct Placement: everything is in the right placement from plans.

Safe Use: drawers and doors open fully with no pinches or obstructions.

Shared Responsibility: contractors often own “room readiness” issues, suppliers own “product fit” issues. Snagging together makes this obvious and easy to resolve.

-

This final stage is where projects get stuck later on, if missed now.

Check for:

Manuals: bed, mechanisms, appliances and specialist items.

Warranties: filed, with clear start dates and terms.

Final Asset List: accurate, matches what’s installed.

Care/Cleaning Guides: for fabrics, finishes, bespoke items.

Spare Parts: provided where specified.

Compliance Certificates: fire / safety / electrical as relevant.

Supplier note: we recommend treating documentation as part of snagging sign-off, not a “send later” item.

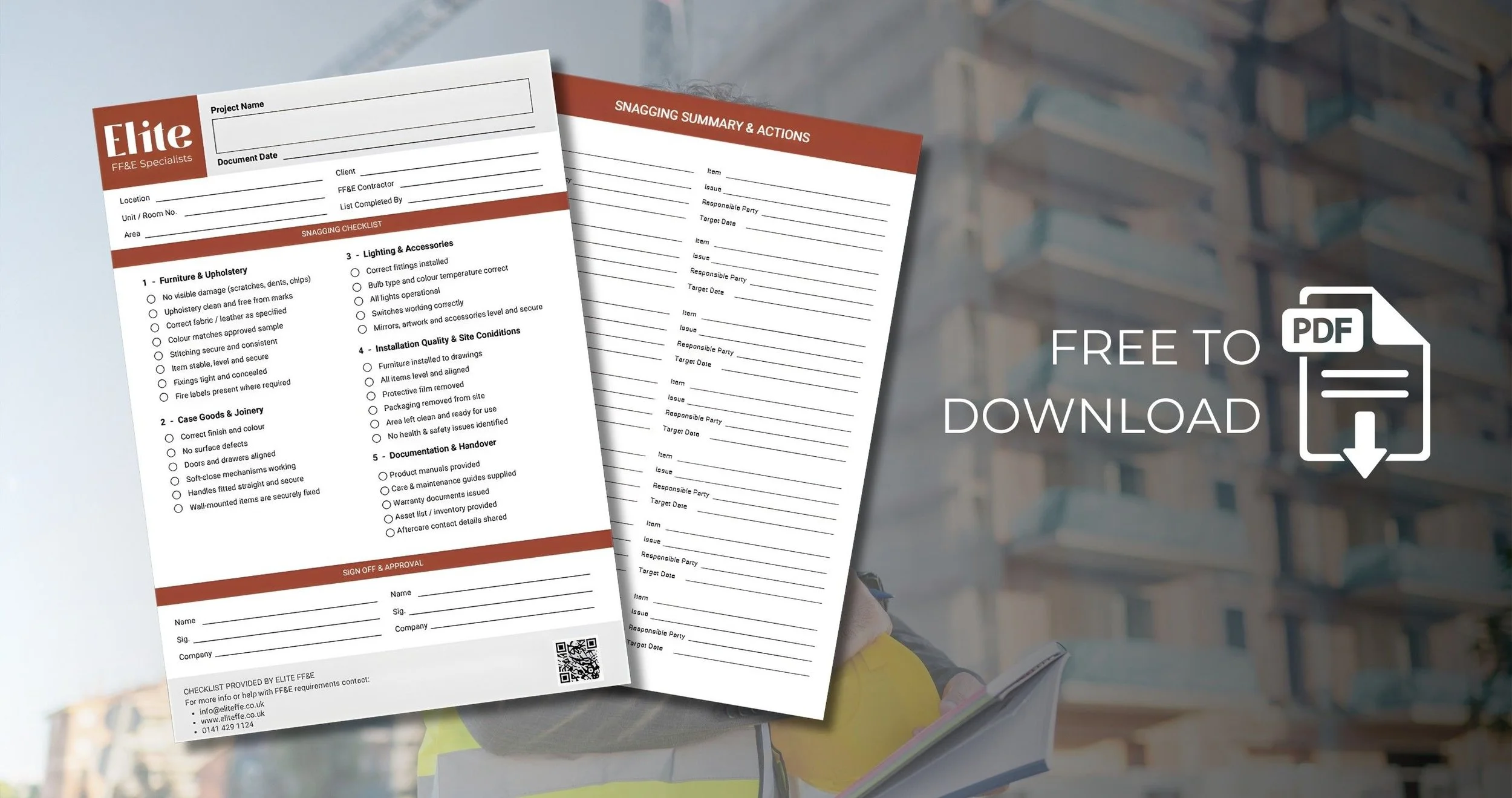

Download our FF&E Snagging Checklist

To help your snagging meeting run smoothly, we have created a simple snagging checklist. This covers all of the basic considerations we recommend you inspect ahead of handover.

Final Thoughts

Supplier-led snagging isn’t about finding faults; it’s about making sure the space is ready for handover, without any nasty surprises.

When snagging is done together, it prevents re-visits, avoids disruptions and protects partnerships. Most importantly, it ensures the finished room feels exactly as intended.

If you’d like a checklist tailored to your projects - hotels, BTR, care or student environment, get in touch and we can discuss your project in more detail.